Researchers from CIGIP participated in the 17th International Conference on Industrial Engineering and Industrial Management (ICIEIM) held in Barcelona on July 6th and 7th, presenting three papers and a poster derived from the AIDEAS Project, funded by the European Commission under its Horizon Europe R&D program. Notably, this significant conference is promoted by the Association for the Development of Engineering Organization (ADINGOR), which brings together professionals in management and R&D working in the field of Engineering Organization.

The AIDEAS Project represents a remarkable effort to integrate cutting-edge Artificial Intelligence (AI) technologies into various aspects of the industrial engineering lifecycle, leading to advancements in machinery design, manufacturing processes, and sustainable practices in the equipment industry. The topics addressed in the AIDEAS Project presentations garnered considerable interest among the Congress attendees. The works that resulted in the presentations were conducted by researchers: Beatriz Andrés, Miguel Ángel Mateo, Juan Pablo Fiesco, and Raul Poler, affiliated with the Center for Research in Management and Production Engineering (CIGIP).

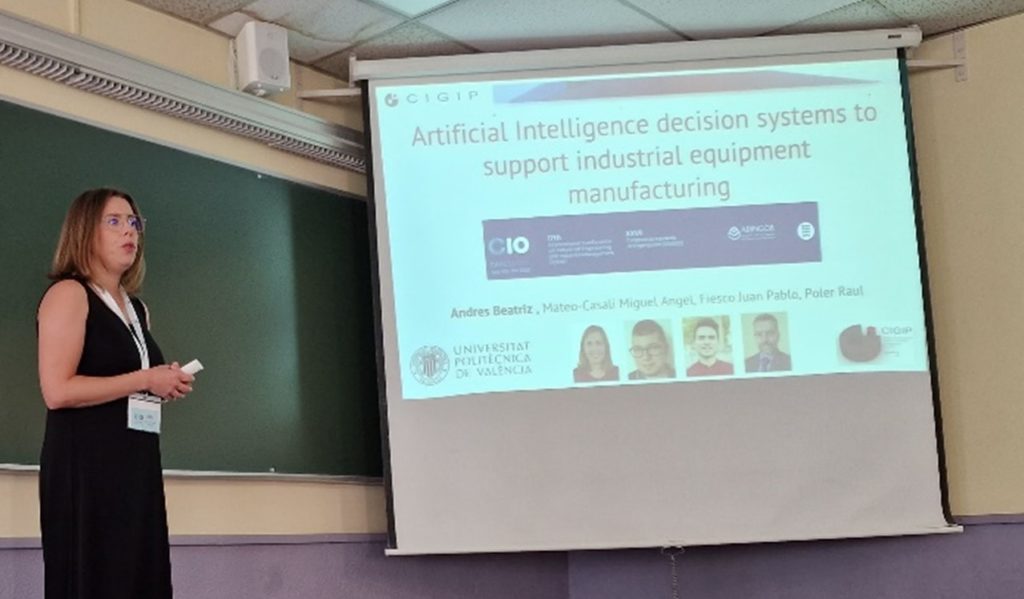

The speech entitled «Artificial Intelligence decision systems to support the industrial equipment Manufacturing» was presented by Beatriz Andrés and showcased the transformative potential of AI-based decision systems in industrial equipment manufacturing. Integrating AI’s predictive capabilities and real-time data analysis allows manufacturers to optimize production processes, improve quality control, and enhance overall operational efficiency. The collaboration between human expertise and AI-driven insights opens doors to greater productivity and competitiveness.

The speech entitled «Optimizing the Use of machinery by applying Artificial Intelligence» was presented by Miguel Ángel Mateo and emphasized how AI can optimize the operational phase of industrial equipment, yielding significant benefits through the incorporation of AI-based predictive maintenance, adaptive control systems, and operational analysis. This leads to increased productivity, reduced downtime, and significant cost savings, contributing to a more sustainable and efficient resource utilization approach.

The speech entitled «Enhancing machinery design through using Artificial Intelligence» focused on harnessing AI algorithms and data analysis to revolutionize industrial equipment design, creating more efficient, reliable, and innovative machines, and setting new standards in industrial engineering to address future challenges.

Lastly, a poster entititled «Repair-Reuse-Recycle assisted with Artificial Intelligence: An equipment industry case» was presented, focusing on the application of AI to promote sustainable practices within the industrial equipment industry, minimizing waste, reducing environmental impact, and adopting a circular economy model by integrating AI-based decision-making in machine repair, reuse, and recycling processes.