Ce.S.I. Centro Studi Industriali

PROFILE:

Ce.S.I. Centro Studi Industriali Srl (CeSI) is an independent SME that focuses its activities on Design, Advanced Engineering, Digital Innovation and Consultancy in four strategic business areas: Manufacturing/Machine tools, Advanced Materials, Transport and Micro-technology.

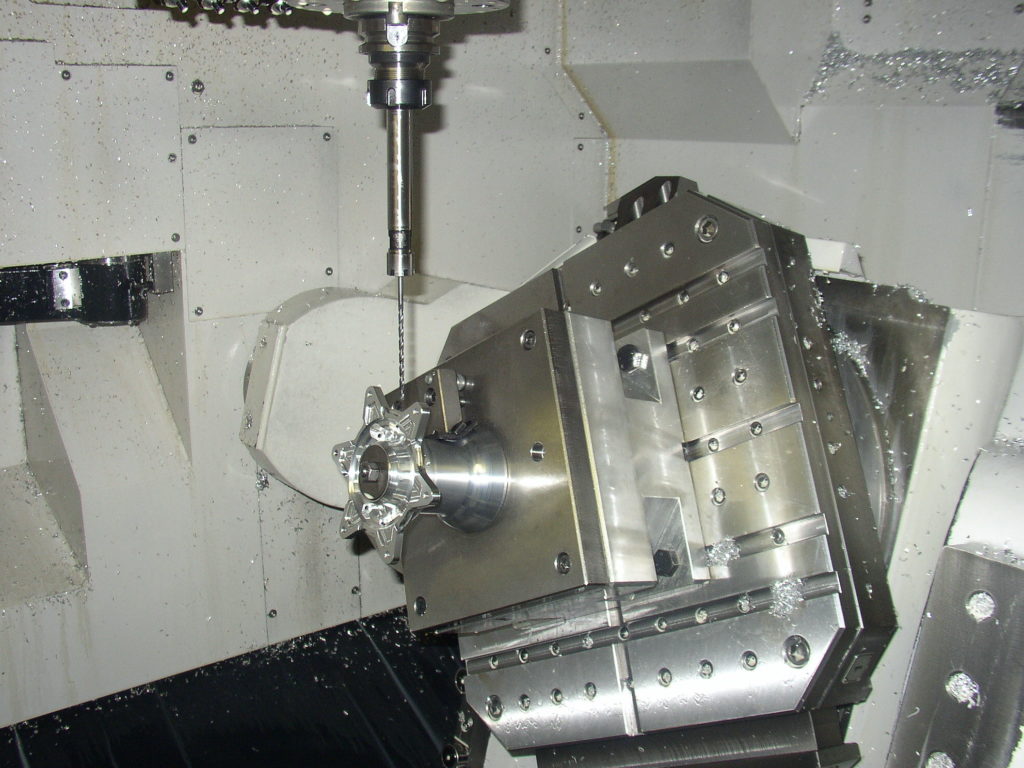

- Manufacturing/Machine Tools

The company core business is represented by the study, design and simulation of innovative equipment solutions focused on performance, reliability, modularity and cost. Ce.S.I. has extensive experience doing this for high-performance precision machinery including CNC machine tools (milling, turning, grinding, laser cutting and boring).

- Advanced Materials

In close collaboration with leading suppliers of material technologies, Ce.S.I. develops advanced, cost – effective and highly integrated product – process solutions based on CFRP composite, multifunctional sandwiches, metal & polymeric foams, smart materials.

- Micro – Technology

Ce.S.I. is speciaized in studying, designing and simulating multifunctional motion units for ultraprecision micromechanical machining processes. Ce.S.I. also provides solutions for micro-positioning systems with inherent AVC (Active Vibration Control) based on high performance smart actuators.

- Transport

Ce.S.I. transfers its design and manufacturing process expertise in the development of innovative green vehicles for road transport and high performance jet engine components.

Ce.S.I. competences have been enlarged to offer also manufacturing services in the field of precision machining. Ce.S.I. manufacturing capabilities include the processes and equipment required for fabrication of a wide range of products in the fields of automotive, motorcycle, aerospace, machine tools, industrial plants, medical and microelectronics industry.

Ce.S.I.’s main competences related to AIDEAS project are:

- Design and simulation of machines/cells and production equipment – digital twin modelling

- Predictive analytics, machine-learning approaches for in-process anomaly detections of machine tools

- Life cycle cost modelling – End of Life strategies assessment

- Broad supply chain network; Presence in the national and international manufacturing panorama

- Access to machine tool builders groups and manufacturing-oriented associations

Finally, Ce.S.I. will also provide a broad user perspective ensuring that the developed solutions are addressing real needs of the field.

CONTRIBUTIONS TO THE AIDEAS PROJECT:

- Coordinating and supporting the definition of requirements and KPIs for AIDEAS solutions with respect to each Pilot use cases

- Bridging activities (AI tools developers <=> Pilots) for integration and deployment of AIDEAS solutions within Design, Manufacturing, Use and End of Life (Repair, Recycle, Reuse) of equipment

- Providing support for the development of AI models to enable Fabrication, anomaly detection and selection of sustainable End of Life strategies

- Providing technical support for the validation of the AIDEAS solutions in the different AIDEAS use cases.

- Contribution towards project dissemination, exploitation, and standardization activities.

EXPECTATIONS:

Ce.S.I. provides services to create substantial new value for its customers. This include methods and technologies to boost digital innovation and transformation toward Industry 4.0. In particular Ce.SI. is already active in the following two key areas:

- Simulation of R&M (Reliability and Maintainability) behaviour of manufacturing equipment

- Machine-Learning and Predictive Analytics. These technologies enable data-driven prognostics (predictive maintenance) of machine tools/equipment as well as in-process quality prediction of produced parts.

AIDEAS project represents an important step forward in industrial digitalization and for Ce.S.I. a great opportunity to enhance its competences in that strategical area. Ce.S.I. expects to increase its service solution portfolio including AI-powered analysis related to Design, Fabrication, Use and End of Life phases of machine tools/production equipment. This integrated approach is expected to boost the transition towards digital, sustainable and zero-defect manufacturing.